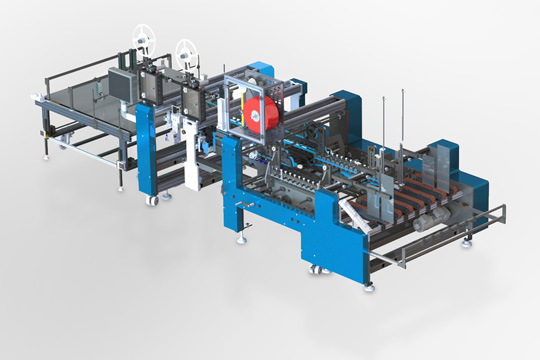

Inter-HST 165

Introduction

With the length of 6,175 meters and weight of around 4,5 tonnes, our standard machine, Inter-HST 165, is capable of processing cardboard format width anywhere between the minimum of 80 millimeters (8 centimeters) and maximum 1.650 mm (1,65 m). That’s just to give you a taste of what our machine has to offer. The Inter-HST also comes equipped with numerous other features and options.

Features

Machine Design

- Open design allows operator to move within the machine

- Safety during production process is ensured with light barriers

- Possible configuration on wheels for easier movement of machine in production hall

Feeder: Perfect aligment is ensured with feeder high flexibilty and various feeding options

- Feed belts easy adjustment to the left and right

- Feed belt angle adjusment for most demanding products

- Dual feed gates with angle adjusment

- Extendable linear guide bar suppport for larger cartons

- Possible configuration with Servo motor for better feeding perfromance and independent adjustment

Side register section : Perfect carton alignment for perfect hotmelt and tape quality

- Double side register section with belts

- Precise adjsument with angled rollers for various material thickness

- Standard size 1200mm and optional customizable size

Delivery Conveyor : Small, light and flexible

- Length 2000 mm and optional customizable

- In line or „L“ shape installation

- Spray element counter and programabille packages counter

- Two pneumatic gates for better alignment on conveyor

Application section

- Open design for easy set up of silicone tape applicator, teartape applicator and hotmelt glue

- Moving applicators from left to right side (and opposite) with linear guides

- Additional drive for teartape applicators for better teartape quality

Teartape section

- Pneumatic teartape applicator with speed up to 13.000 pcs/h

- Servo teartape applicator with speed up to 20.000 pcs/h

- Tape rupture control

Hotmelt

- Hotmelt melting unit (with gear pumps) controlled on INTER HST HMI

- Hotmelt head controlled on INTER-HST HMI

- Pneumatic pusher for optimal counter pressure on hotmelt head and better hotmelt quality

Envelope solution: Folding and gluing envelope-like boxes

- Adittional pneumatic hotmelt unit for gluing

- Upgradable folding module for application section

Control system

- Specially designed so that the operator has insight and can control the entire work process of the machine

- Memorable working settings

Specifications

Processed materials

- Carton boards: max 800 g/m2

- Corrugated Flute type: G,F,E,D,B,C,A,BC,AB,EE,BE

Capability

- Speed: 20 to 200 m/min

- Thickness of folded box: max 40 mm

- Blank width: 200 mm to 1650 mm

Dimension and weight

- Length: 6.2m

- Width: 2.4m

- Height: 2.45 m

- Net weight: 5 t

Installation

- Power required: cca. 15 kW,400 VAC

- Compressed Air: 6 bar

- Air compressor capacity: 500 l/min

View it in action

Don't miss out on our services

Our services include: machine relocation, maintenance and repair, modernization and training & coaching.

Machine relocation